Siak Transfers Limited are the UK's leading supplier of quality screen printed ceramic decals. Ceramic Decals (lithographs or transfers) are used to apply printed design to ceramic objects - Tableware, hotelware, tiles, ornaments, plaques and sanitaryware. Decals are printed onto a gum or wax coated paper. The image is coated in a protective layer that facilitates its transfer to the desired object.

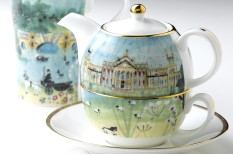

Onglaze decals

The most common, lowest temperature and widest colour palette of the ceramic decal system. Ceramic decals are applied to the glazed ceramic surface and fired in ranges of 800 - 900 degrees.

Inglaze decals

When a higher durability ceramic decal product is required. Typically fired between 1100 and 1300 degrees. At this higher temperature the inglaze ceramic decal sinks into the glaze providing higher resistance.

Ceramic relief decals

Fired at onglaze temperatures of 820 degrees, ceramic relief decals are used to provide a tactile feel and shape to the surface of the ceramic article. An ideal alternative to transform the shapes of standard white ceramic pieces.

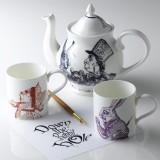

Metallic effect decals

At onglaze firing temperatures ceramic metallic decals are used to give a lustrous effect to the decorated ceramic surface. A low cost alternative to precious metals that gives a high value feel.

Underglaze decals

Ultimate durability is provided by this type of twice fired ceramic decal. The decal is placed onto the bisque plate and fired to harden. The glaze is applied, and the product fired again to seal the decal completely.

Get in Touch

Manufacturing decals for ceramics and glass for the past 30 years in the heart of the Stoke-On-Trent

CONTACT FORM